With the progress of society and the development of science and technology, how to reduce the workload and improve work efficiency has become a common concern of all sectors of society. The environmental health sector is no exception. The sanitation workers who serve the people are busy cleaning and beautifying the city. Why? Tieling 240L dustbin More and more popular? So far, many sanitation workers in domestic cities are still using old-fashioned sanitary garbage cans and sanitary vehicles. Due to many factors such as material selection and manufacturing method, the environmental sanitation waste will change color and weaken acid and alkali, thus reducing the service life of environmental sanitation waste under the condition of high working intensity. Poor sealing results in secondary pollution of the environmental sanitation garbage can, which emits bad smell and avoids pedestrians. All kinds of bad environment bring a lot of inconvenience to our staff.

Tieling 240L dustbin It can adapt to different environments. In our grasp of the environment, we still need to show more beauty of our family life. On the one hand, only by doing a good job of hygiene can we make a real family full of warmth. When the overall change of plastic trash can can realize its own value and surpass itself, it will show a momentum of development. The vast market and unlimited development potential have brought intangible power to life and environmental protection. After several years of transformation, Tieling 240L dustbin It has occupied half of the world's environmental protection ranks. It is not only a household plastic garbage can, but also a plastic garbage can used in the streets or public places. The plastic garbage can will continue to flourish at all stages of its rapid development and outstanding practical value. Many families can say that they have an ordinary garbage can. When designing plastic trash cans, plastic trash can manufacturers also consider plastic trash cans used in streets and public places. In this way, the use of better and better results will be recognized by many people. Therefore, the value of plastic trash can will naturally become a magic weapon for cleaning.

240L dustbin Manufacturer The current situation of garbage cans in the scenic spot is as follows: 1. The number of garbage cans is insufficient to meet the needs of tourists; 2. The management and maintenance are not in place, and the health condition is worrying; 3. The design concept of garbage cans in tourist attractions is backward, which creates a sense of discord with the scenic spots and affects tourists' playing mood; 4. Lack of design creativity and cultural atmosphere, and fail to make good use of the cultural value of the scenic spot itself. 5. The city we live in has become the focus of attention because there is no guiding civilized persuasion. Among the numerous scenic facilities, they are not important facilities and are often ignored by designers. However, in the actual use and setting, there are many problems worth thinking about by scenic workers. If these problems are properly handled, tourists will get more convenience, make the design of the scenic area more harmonious and perfect, and guide tourists more, Even the social atmosphere is developing towards a more civilized direction.

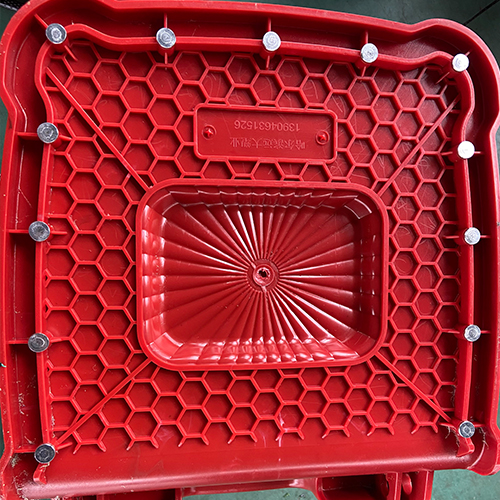

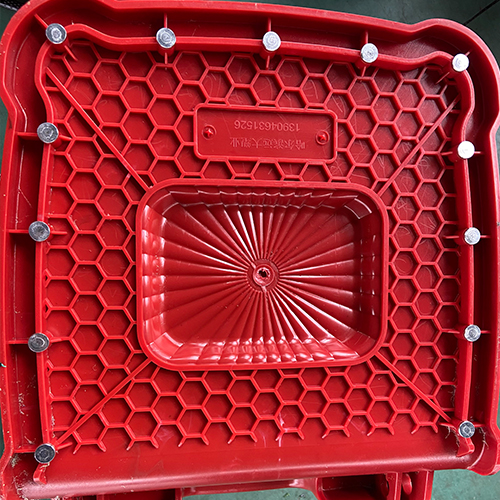

Plastic trash cans are becoming more and more popular. Whether you are walking downstairs or walking in the park, you will probably see it. But we probably don't know how to make plastic garbage cans. Now 240L dustbin Manufacturer Let's go over it. Tieling 240L dustbin In general, it is made of special HDPE by one-time injection molding. Because it uses 100% high-density polyethylene or polypropylene, it is an environmental protection product that can be recycled. Because of its one-time injection molding and no crack layout in the bucket, the outdoor plastic garbage can is more durable. And because its material makes the inside of the bucket slippery, it can effectively reduce the waste storage and is convenient and clean. Generally, the plastic trash can can be stacked when designed, which can save a lot of space for transportation and storage. Compared with other examples of garbage can products, your five minute production time is beyond the reach of other examples of garbage cans. In addition, its corrosion resistance, heat resistance and antifreeze characteristics make it widely used in various industries.

stay Tieling 240L dustbin In it, we try to establish the method of classified garbage disposal. Some things are easy to produce odor, and those that cannot be recycled are put together. Properly distinguish and timely clean up the smelly garbage will reduce the odor, which will also have a better effect from the perspective of long-term use, so we should know these methods. Classified garbage dumping is now implemented in many cities, and the effect will be very good. in use Tieling 240L dustbin In some places, the service life is very long, while in some places, the service life is relatively short, which is affected by many factors. There are correct ways to extend the service life, so that it can be better used in the future. Therefore, the sanitation articles section suggests that you must take these situations into account correctly.

As we all know, a good way to dispose of garbage is to throw it into classified garbage cans. Compared with other garbage cans classified by text, plastic garbage cans classified by color with large mouth and large capacity are popular. Well, you know Tieling 240L dustbin How is it made? below 240L dustbin Manufacturer Let's introduce it to you. It is believed that many people are familiar with plastic trash cans, because the increasingly popular plastic trash cans are favored by the society because of their recyclable materials, high choice of colors, simple process of one-time injection molding in the production process, superposition in the transportation process, product diversity, etc. 1. Of course, the garbage can with high temperature injection molding like this has designed a mold we need. Of course, the size and precision of the mold are designed according to the size and precision of the product we want. 2. Prepare the raw materials. Most of them are making garbage cans for HDPE. 3. One time injection molding in the injection machine. 4. Some burr processing and enterprise logo after cooling, and patterns required by customers.