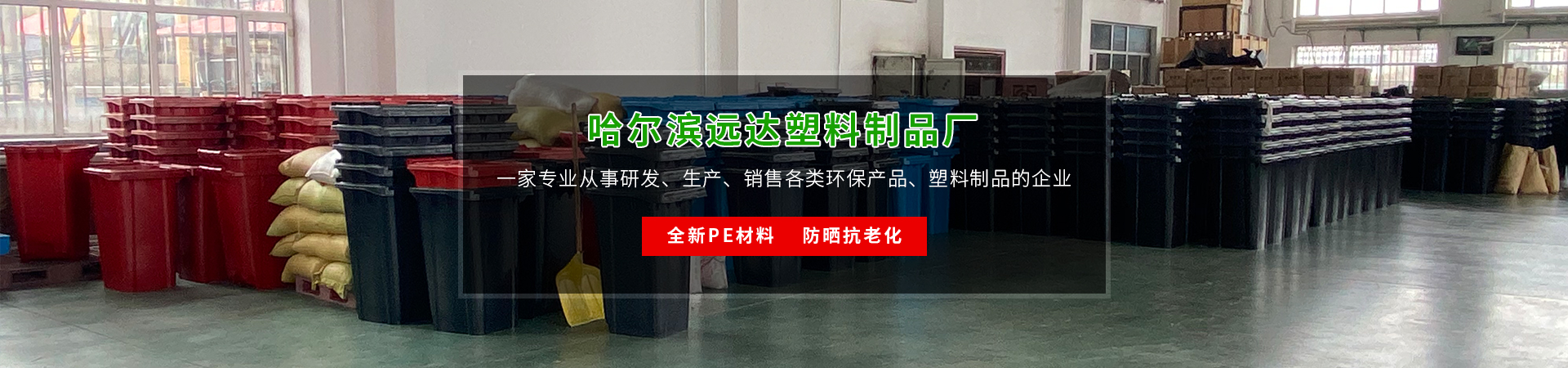

240L plastic trash can Functions and features of:

1. The plastic barrel is beautiful, smooth inside and outside, seamless without welding, light weight, good strength, impact resistance, corrosion resistance, non-toxic and tasteless, and convenient transportation.

2. Long service life. Under normal filling, transportation and loading and unloading conditions, the warranty period is 1.5 years.

3 The technical parameters of the products are strictly in accordance with the national standards, and the product appearance design and product dimensions can also be customized according to needs.

4. It can be used for hot filling, and the general temperature should not exceed 60 ℃. After hot filling, the lid and stacking shall not be closed until the contents have cooled sufficiently and dropped to room temperature.

5. If it contains easily dispersed chemicals, it can be equipped with a cover with exhaust function to avoid the danger of overpressure during transportation, while ensuring the sealing performance of the liquid.

Product features: the whole process of storage, stacking and canning can greatly save space and materials. Light weight, low temperature resistance, corrosion resistance, pollution reduction, super clean, acid resistance, alkali resistance, high temperature resistance, non-toxic, sterile, tasteless, and excellent scalability and impact resistance meet the requirements of medical testing.

The main raw material for the production of plastic drums is polyethylene (PE), or PE for short, which is a high molecular organic compound formed by the addition polymerization of ethylene. Polyethylene is recognized as a food contact material in the world, non-toxic, tasteless, odorless, and in line with food packaging health standards. Polyethylene film, light and transparent, has the properties of moisture-proof, oxygen resistance, acid resistance, alkali resistance, general air tightness, excellent heat sealing, and is known as the "flower of plastics". It is an important material used in plastic packaging and printing.

polyvinyl chloride

Polyvinyl chloride (PVC for short), with the molecular formula of (CH2-CH2CL) n, is a major class of vinyl polymers. It is the second largest plastic variety in the world after polyethylene at present, and its domestic output ranks first among plastics. In the printing industry, PVC color calendering film and transparent glazing film are often used to make packaging and decoration of books, folders, tickets and other covers.

Shrink film

Shrinkfilm is a thermoplastic film that is stretched and oriented during production and shrinks when exposed to hot air treatment or infrared radiation during use. After heat treatment, the film is tightly wrapped on the package, and the shrinkage force reaches the maximum value in the cooling stage, which can be preserved for a long time.

low density polyethylene

Low density polyethylene, or LDPE for short, is a large variety used in plastic packaging and printing industries in various countries. The specific gravity is 0.92~0.93, which can float in water. The crystallinity is low (60%), and bulk polymerization is carried out at the pressure of 1000~3000kg/C ㎡, so it is also called high-pressure polyethylene. At 23 ℃, the density is about 0.92. Due to poor calendering formability, it is suitable for blow molding to process tubular films. It is suitable for food packaging, fiber products packaging and daily chemical products packaging. Marking of degradable plastic bags

High density polyethylene

High density polyethylene (HDPE for short). The density is 0.941~0.965g/cm3. It is polymerized at low pressure, so it is also called low pressure polyethylene. It is milky white, indicating poor gloss. The film can be processed by blow molding and T die extrusion. Heat resistance, cooking resistance, cold resistance and freezing resistance, good moisture-proof, gas proof and insulation performance, not easy to damage, and twice the strength of LDPE. Easy to open. It is known as "paper like plastic film" because of its strong paper like property.

Polypropylene film

Biaxially stretched polypropylene film, also known as biaxially stretched polypropylene film, abbreviated as BOPP, is characterized by tensile molecular orientation, mechanical strength, folding strength, air tightness and moisture resistance superior to ordinary plastic film. Compared with cellophane per unit area, the unit price is lower than cellophane. Because of the excellent transparency of the film, the color reproduction after printing is particularly bright and beautiful, and it is an important base material for plastic composite flexible packaging.

Scope of application:

Plastic packaging barrels are mostly used for the storage and transportation of various liquids. They have good characteristics for special dangerous goods. They are not fragile, rusty, light, and not easy to deform, and have excellent oil resistance and strong corrosion resistance. They are suitable for packaging dangerous goods that need heat preservation, moisture resistance, pressure resistance, and corrosion resistance. It is mainly used to hold liquid and solid articles in chemical raw materials, pesticides, lubricants, coatings, medicine, food, hardware, electronics, electromechanical and other industries. Specifications range from 100mL to 200L.