Plastic barrels are mostly used for the storage and transportation of various liquids. They have good characteristics for special dangerous goods packaging. They are not fragile, rust free, light in weight, and have excellent oil resistance and strong corrosion resistance. They are mostly used for dangerous goods packaging that requires heat preservation, moisture resistance, pressure resistance, and corrosion resistance. Plastic barrels are mostly made of polyethylene, polypropylene, polyester and other plastics by blow molding, injection molding, blistering, and roll molding. They are mostly used to hold liquid and solid articles in chemical, pesticide, medicine, food, hardware, electronics, electromechanical and other industries.

Open/close plastic bucket and 1000L container plastic bucket. It can be used for goods storage or transportation and turnover. At present, the plastic barrel produced by the rotational molding process has a large capacity of 50 tons.

Some products can be used for hot filling, and the general temperature should not exceed 60 ℃. After hot filling, the lid and stacking shall not be closed until the contents have cooled sufficiently and dropped to room temperature. The weather resistance of 60 ℃ - 40 ℃ is excellent.

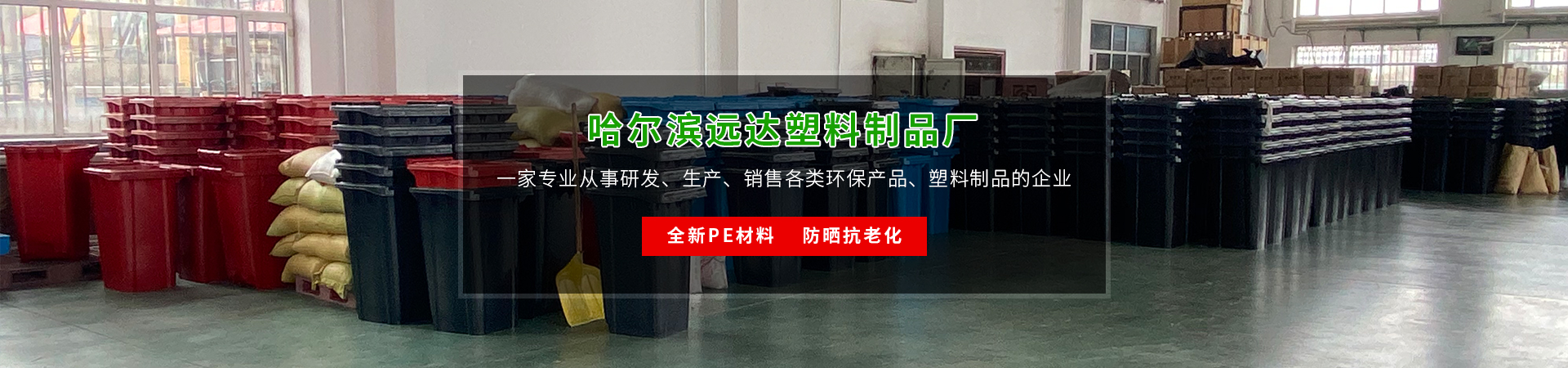

Plastic garbage cans, plastic sanitation garbage cans and two wheeled plastic environmental protection garbage cans are mainly composed of polypropylene polypropylene or 100% high-density polyethylene HDPE Sanitation products manufacturer I will give you a detailed analysis of the plastic trash can's knowledge of these two materials:

1、 PP polypropylene two new plastics

1. Raw material: 100% high quality polypropylene, the barrel body and the barrel cover are respectively made by one high-pressure injection molding.

2. Features: (1) Acid resistance, alkali resistance, corrosion resistance and strong weather resistance; (2) The round corner design of the delivery port is safe without sharp edges; (3) The surface is smooth and clean, reducing waste residue and easy to clean; (4) It can be overlapped to facilitate transportation and save space and cost; (5) It can be used normally within the temperature range of - 30 ℃~65 ℃; (6) There are many colors to choose, which can be matched according to the classification needs; (7) It is widely applicable to various environments, and can also be used for garbage sorting collection, such as property, factory, sanitation, etc.

2、 100% HDPE

1. HDPE with high impact strength is selected as the raw material for the plastic trash can, which is made by one-time injection molding and has good overall performance. It is itself a recyclable environmental protection product.

2. Raw material: 100% high density polyethylene (HDPE) is used. The body and lid of the four-wheel mobile plastic garbage can are respectively molded once.

3. Features: (1) 100% high density polyethylene or polypropylene raw material injection manufacturing, durable. (2) New raw materials can effectively prevent the corrosion of weak acids and bases. (3) Seamless structure design, leak proof structure 100% passed the test. (4) The inside of the bucket is smooth and clean, reducing garbage residue and easy to clean. (5) The barrel body, box mouth and bottom are specially reinforced and thickened to withstand various external forces. (6) It can be overlapped to facilitate transportation and save space and cost. (7) It can be used normally within the temperature range of - 30 ℃~65 ℃.