When it comes to garbage cans, we are all familiar with them. After all, there are garbage cans around us and they have made great contributions to our beautiful environment. But how much do we know about such garbage cans that serve us all the year round? How many kinds of garbage cans are there?

1. Floor trash cans are those trash cans that we can place in public places such as parks and hotels to throw garbage and soot. There are also many types of floor trash cans. We can classify them according to their materials: glass trash cans, steel and wood trash cans, marble trash cans, and stainless steel trash cans.

Glass plate garbage can: as the name implies, it is a garbage can made of glass, beautiful, corrosion resistant, but fragile and difficult to recycle.

Steel and wood garbage can: This is a kind of specially treated wood plate, which is embedded on the steel structure garbage can. It is a kind of beautiful garbage can, which is durable and beautiful, but only damaged and difficult to repair.

Marble trash can: It is similar to the steel and wood trash can, but the wooden board becomes marble.

Stainless steel trash can: I won't say more. There are such trash cans everywhere around us.

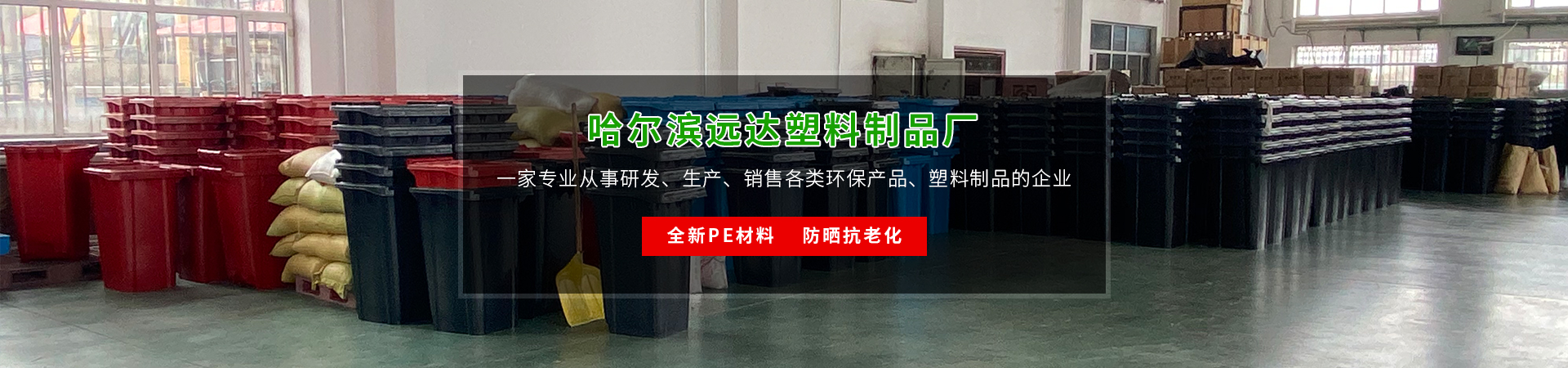

2. Sanitation trash can is a kind of trash can commonly used by sanitation workers. It is generally used to collect domestic garbage with large capacity. It is generally made of stainless steel, plastic and other durable materials. According to functional materials, we can divide them into environmental garbage cans, classified garbage cans, circular garbage cans, FRP garbage cans, steel and wood garbage cans, plastic garbage cans, etc.

Environmental garbage can: environmental garbage can is mainly used to collect recyclable garbage for secondary utilization.

Classified garbage cans: similar to environmental garbage cans, but their main function is to classify garbage, collect recyclable and non recyclable garbage. Recently, people have been talking about garbage classification mainly using such garbage cans.

In life, plastic trash cans often accompany us. It can be said that we cannot look up and look down. We know little about this neighbor who often accompanies us. So 240L plastic trash can How to make it, and what knowledge do you have in the production of plastic trash cans? Let's learn about this knowledge.

We should first understand the plastic trash can from its raw materials. Usually, the raw materials for making plastic trash cans are mostly high-density polyethylene HDPE or polypropylene PP, while the raw materials for sanitation plastic trash cans are generally high-density polyethylene HDPE, mainly because this material can be recycled. Let's take a look at the characteristics of the garbage cans made of these two materials:

HDPE plastic trash can

1. The garbage can is molded by injection molding, which is worry free, solid and durable.

2. Acid and alkali resistance, no need to worry about corrosion.

3. The material surface is smooth, easy to clean, and effectively resistant to corrosion.

4. Special places, such as the barrel body and the barrel mouth, can withstand external forces after thickening.

5. It can be overlapped to facilitate transportation and save space use cost.

6. It can be recycled, environmentally friendly and clean.

Polypropylene plastic trash can (PP)

1. It has strong acid resistance, alkali resistance and weather resistance.

2. The color is variable for the manufacturer to choose.

3. It can be used for different environments and different garbage collection.

4. One time injection molding, smooth surface and space saving are similar to HDPE plastic trash cans.

Plastic trash cans are mostly made by injection molding. The wall thickness of the body is not the main reason for determining the toughness of the body. Its toughness is mainly determined by the materials used, and is also related to the mold and injection molding equipment. The raw materials of the plastic trash can are evenly distributed during the injection molding process to reduce the formation of local pressure; The design of increasing radian inside the bucket bottom is concave, which naturally reduces the impact on the bucket bottom. The unique design of the outer side of the bucket bottom makes the bottom form a distance of about two centimeters from the ground. It does not directly contact the ground, making the garbage can be placed more smoothly, and can also reduce wear. Generally, the design of the plastic bucket lid is people-oriented, which reduces the impact between the bucket lid and the body, Reduce noise, extend service life, and make the cleaning personnel more comfortable and easy to work.