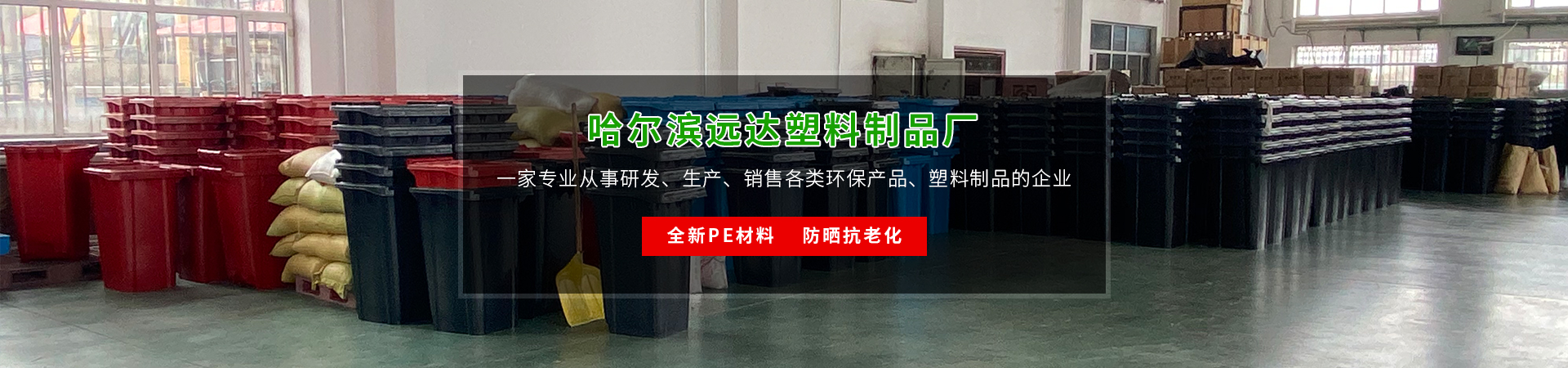

Plastic garbage can manufacturer Remind you that plastic garbage cans are widely used for public sanitation, garbage classification in the process of centralized collection of domestic garbage and automatic garbage dumping with sanitation vehicles. It is a good tool for garbage transportation during the centralized treatment of medical waste.

1、 100% HDPE

1. Overview: (HDPE)

The HDPE (low pressure high density polyethylene) with high impact strength selected as the raw material for the plastic trash can is injected once and has good overall performance. It is itself a recyclable environmental protection product. Compared with other types of trash cans, plastic trash cans have a shorter production time (usually a plastic trash can can be produced in about 5 minutes). When plastic trash cans are designed, the body can be stacked, which reduces the volume of logistics, transportation and storage of products. The plastic garbage can is more superior to the garbage can made of other materials, and the plastic lid is tightly filled, the body will not deform for a long time, the box structure will not become fragile and deformed, and the characteristics of heat resistance, antifreeze, acid resistance, alkali resistance, easy cleaning of the box are now widely used.

2. Raw materials:

Use 100% high density polyethylene (HDPE).

The can body and the end are respectively molded once.

3. Features:

(1) It is made of 100% high-density polyethylene or polypropylene raw materials by injection molding, which is sturdy and durable.

(2) New raw materials can effectively prevent the corrosion of weak acids and bases.

(3) Seamless structure design, leak proof structure 100% passed the test.

(4) The inside of the bucket is smooth and clean, reducing garbage residue and easy to clean.

(5) The barrel body, box mouth and bottom are specially reinforced and thickened to withstand various external forces (such as collision, lifting and falling).

(6) It can be overlapped to facilitate transportation and save space and cost.

(7) It can be used normally within the temperature range of - 30 ℃~65 ℃.

2、 PP: two new plastics

1. Raw materials:

100% High Quality Polypropylene (PP)

The barrel body and the barrel cover are respectively made by one-time high-pressure injection molding.

2. Features:

(1) Good acid resistance, alkali resistance, corrosion resistance and weather resistance;

(2) The round corner design of the delivery port is safe without sharp edges;

(3) The surface is smooth and clean, reducing waste residue and easy to clean;

(4) It can be overlapped to facilitate transportation and save space and cost;

(5) It can be used normally within the temperature range of - 30 ℃~65 ℃;

(6) There are many colors to choose, which can be matched according to the classification needs;

(7) It is widely applicable to various environments, and can also be used for garbage sorting collection, such as property, factory, sanitation, etc;