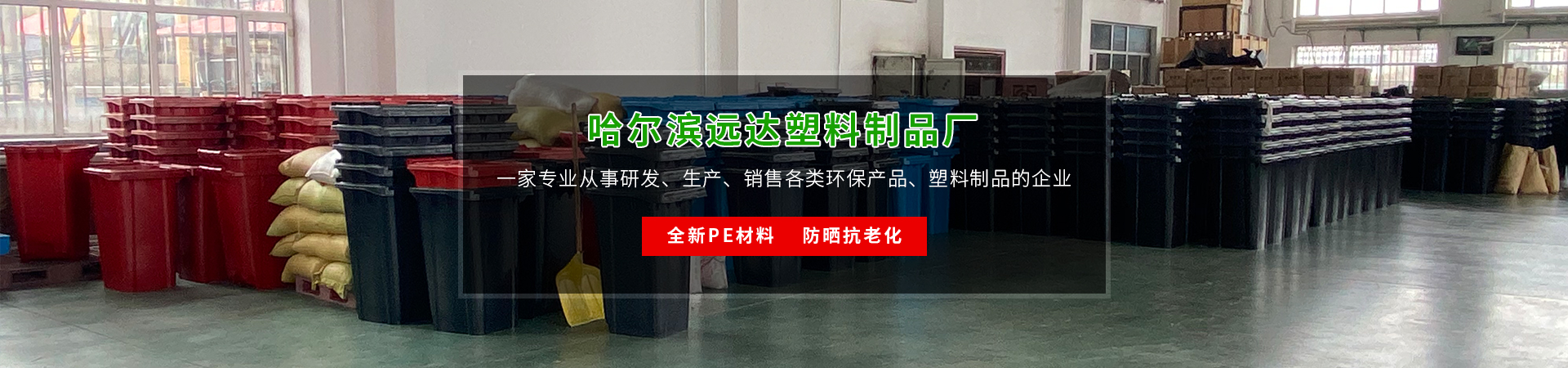

We usually use a variety of garbage cans, of which plastic spraying garbage cans are a very common manufacturing process. Compared with traditional paint spraying garbage cans, plastic spraying garbage cans have excellent characteristics, Today, we will lead you to understand the plastic spraying process in the production process of garbage cans: the principle of plastic spraying is to use electrostatic powder spraying equipment (electrostatic plastic spraying machine) to spray the powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating; The powder coating becomes the final coating with different effects (different kinds of effects of powder coating) after high-temperature baking and leveling curing; The spraying effect is superior to the spraying process in terms of mechanical strength, adhesion, corrosion resistance, aging resistance, etc.

Harbin plastic trash can Plastic spraying process:

1. Pretreatment: purpose: remove the oil stain, dust and rust on the surface of the workpiece, and generate a "phosphating layer" on the surface of the workpiece that is corrosion resistant and can increase the adhesion of the spraying coating. Main process steps: degreasing, derusting, phosphating and passivation. After pretreatment, not only is the surface of the workpiece free of oil, rust and dust, but also a uniform and rough gray phosphating film that is not easy to rust is generated on the original silver white shiny surface, which can both prevent rust and increase the adhesion of the plastic spraying layer.

2. Electrostatic spraying: purpose: to evenly spray the powder coating on the surface of the workpiece. Special workpiece (including the position where electrostatic shielding is easy to occur) should be sprayed by high-performance electrostatic spraying machine. Process steps: Apply a layer of powder coating evenly on the surface of the workpiece based on the principle of electrostatic adsorption. The fallen powder is recycled through the recovery system and can be reused after screening.

3. High temperature curing: purpose: heat the powder coating on the surface of the workpiece to the specified temperature and keep it warm for a corresponding time to melt, level and solidify it, so as to obtain the desired surface effect of the workpiece. Process steps: push the sprayed workpiece into the curing furnace, heat it to the preset temperature (generally 185 ℃), and keep it warm for a corresponding time (15 minutes); Open the furnace and take it out for cooling to get the finished product.

4. Decoration treatment: purpose: to make the workpiece after electrostatic spraying achieve a special appearance effect, such as various wood grains, patterns, and polishing. Process steps: glazing; Transfer printing and other processing technologies.

Advantages of plastic spraying

1. Compared with the traditional painting process, the electrostatic spraying process has significant advantages, no thinner is needed, and the construction has no pollution to the environment and no toxicity to the human body;

2. The coating has excellent appearance quality, strong adhesion and mechanical strength;

3. The curing time of spraying construction is short;

4. The corrosion resistance and wear resistance of the coating are much higher; No primer required;

Features of plastic trash can

(1) Acid resistance, alkali resistance, corrosion resistance and strong weather resistance;

(2) The round corner design of the delivery port is safe without sharp edges;

(3) The surface is smooth and clean, reducing waste residue and easy to clean;

(4) It can be overlapped to facilitate transportation and save space and cost;

(5) It can be used normally within the temperature range of - 30 ℃~65 ℃;

(6) There are many colors to choose, which can be matched according to the classification needs;

(7) It is widely applicable to various environments, and can also be used for garbage sorting collection, such as property, factory, sanitation, etc;

Cleaning advantages of plastic trash cans

(1) Plastic trash cans are relatively simple to process. They are made of energy-saving materials. In use, they not only reduce a lot of costs, but also improve the service life. The use of garbage cans is also very common in more homes, such as bedrooms, kitchens, bathrooms, living rooms, etc., which are used everywhere. But when more is used, we also need to have a good experience of energy conservation and environmental protection in our daily life.

(2) The plastic trash can also has a perfect display for more cleaning. We habitually throw garbage into the trash can, which will also have a better educational significance for many children, promoting the use of different materials. Easy cleaning is also the advantage of plastic garbage cans, which more shows the more humanized design concept of garbage cans in use.

(3) Plastic trash cans are well used in many environments. We still need to show more beautification in our home life when we master the environment. Only by doing a good job in sanitation can we show a truly warm family.