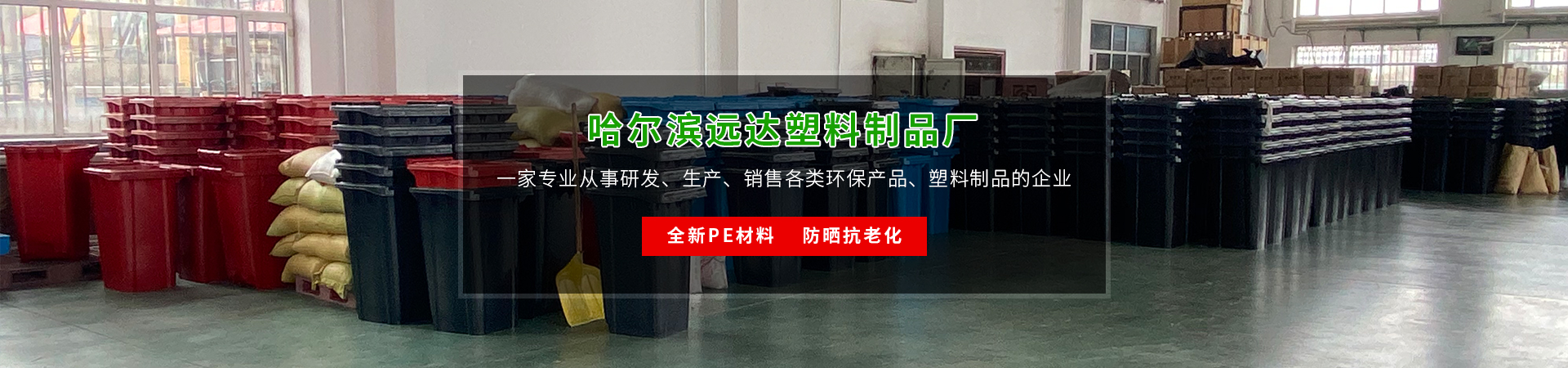

240L plastic trash can It is a product used in many industries, such as cleaning and sanitation, which brings clean to various public places in the city and can be seen everywhere on the streets. It is an environmental protection product that is ubiquitous in real life. There are more than 500 million garbage cans in use in China, 66% of which are made of iron and wood, while the recyclable plastic garbage cans only account for 30%, so there is still a lot of space for plastic garbage cans. The plastic garbage can itself is a recyclable environmental protection product. Compared with other types of garbage can products, the production time of the plastic garbage can is relatively short. When the plastic garbage can is designed, the body can be stacked, and the volume is reduced, which brings great convenience to the logistics transportation and storage of products.

We offer two options for outdoor plastic trash cans. One is HDPE, which is generally interpreted as a brand new material. HDPE (low pressure high density polyethylene) with high impact strength is used as raw material for one-time injection molding, which has good overall performance, and is itself a recyclable environmental protection product. When designing plastic trash cans, the body can be stacked, which can reduce the volume of logistics and storage, and the transportation cost is superior to other products' trash cans. Moreover, the plastic lid is tightly filled, the body will not deform for a long time, the box structure will not become fragile and deformed, and the container is now widely used due to its characteristics of heat resistance, frost resistance, acid resistance, and easy cleaning. Every two kinds of materials are made in China, that is, recycled materials. Recycled materials are recycled plastic products, which are different in service life. Generally, the service life of PE materials is 3-5 years, while that of domestic materials is 1-3 years.

Now let's learn about the usage characteristics of some plastic trash cans!

1. Use 100% high density polyethylene (HDPE) or polypropylene (PP);

2. The barrel body and lid are respectively molded once, which is firm and durable;

3. New raw materials can effectively prevent corrosion of weak acids and bases;

4. Seamless structure design, leak proof structure 100% passed the test;

5. The inside of the bucket is smooth and clean, reducing garbage residue and easy to clean;

6. The barrel body, box mouth and bottom are specially reinforced and thickened to withstand various external forces (such as collision, lifting and falling);

7. It can be overlapped to facilitate transportation and save space and cost;

8. It can be used normally within the temperature range of - 30 ℃~65 ℃; 9. There are many colors to choose from, which can be matched according to the classification needs.